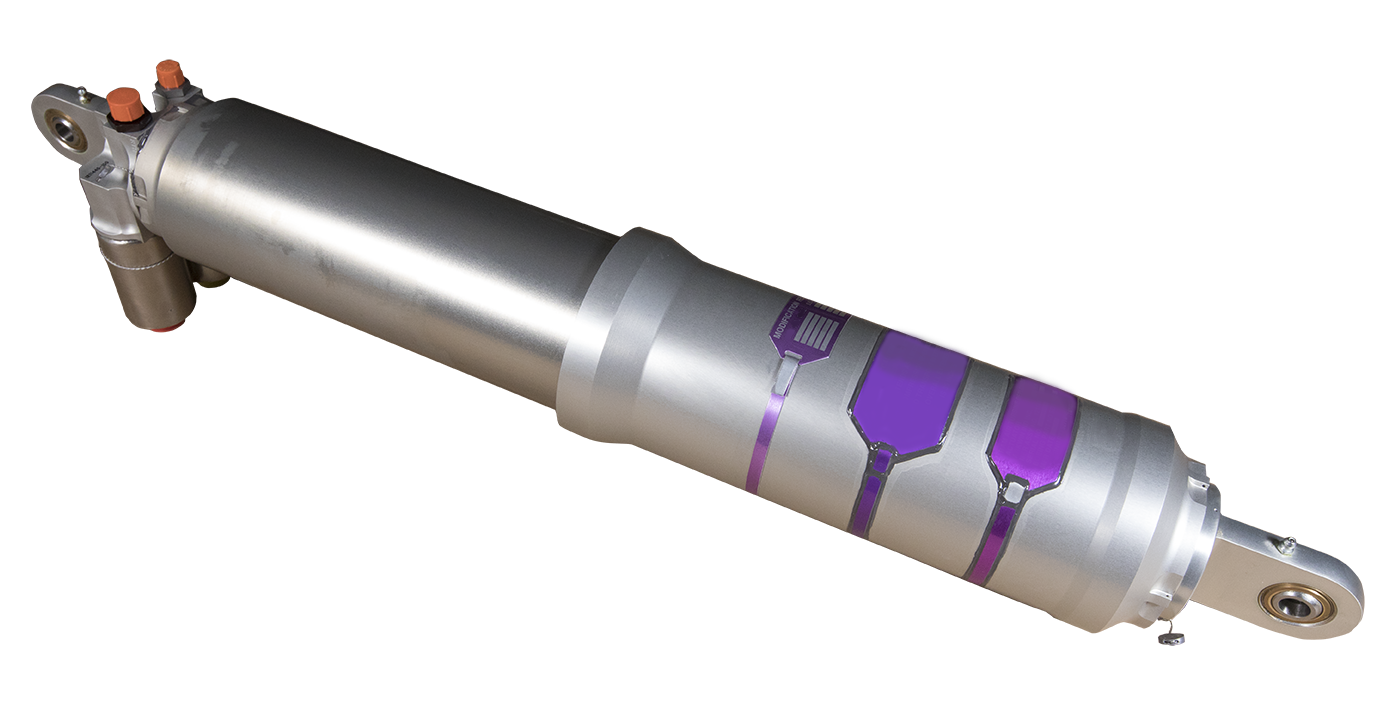

Ram Air Turbine Actuators

The Ram Air Turbine (RAT) actuators deploy the RAT in the rare case when an aircraft loses power. The RAT then works to supply power necessary to control and land the aircraft.

Select Platforms

From the 747 Ram Air Turbine to the Airbus model, we offer a wealth of options.

Airbus A318/319/320/321

Airbus A340/500/600

Airbus A330

Airbus A400M

Airbus A350

Boeing B777

Boeing B757

Boeing B747-8

Dassault 7X

Gulfstream G650

Arkwin Pedigree

We are the technical expert in all things hydraulic for aerospace and defense. Our expertise allows us to satisfy design and performance specifications that others simply cannot. We design, test, manufacture, and support precision hydraulic and fuel system components for civil and military fixed-wing aircraft, helicopters, spacecraft, and turbine engines. Our pedigree goes back nearly 70 years. We have been on board most major civil and military airframes since the 1950s. Our Rapid Custom Product Development (RCPD) team works hand in hand with our customers as an extension of their design team. Through our nimble process-oriented culture, broad in-house capabilities, and operational discipline, we target 100% on-time delivery each and every day.

Product Resources

Other Arkwin Products

Fuel Driven Actuators provide actuation force to direct engine control components and provide electrical feedback of vane position to the engine computer. Our stable of proven high reliability, low maintenance, and fire-resistant designs are capable of >250,000 cycles and operating pressures up to 2,250 psig. We offer multiple mounting options, linear position sensing transducers, 3”+ diameter bores, and 3.5”+ strokes with servo valve applications in master/slave configurations.

Arkwin’s expert engineering team uses the latest design software to convert concepts into reality for a multitude of installations. Arkwin has designed and manufactured over 125 unique hydraulic actuator designs, incorporating numerous customer options to fit customer specifications. Engine manufacturers rely on Arkwin’s expertise in designing the right actuator to meet their strict design and performance requirements. Arkwin actuators can be found in some of the most successful engine application installations in aerospace, and we continue to refine and develop new technologies to meet the needs of engine manufacturers worldwide. We offer a multitude of integrated control options on all types of actuators.

Thrust reverser systems help to enable shorter landing distances and reduce wear on the braking system by slowing down the aircraft after touch-down. The actuator extends to deploy the system and retracts to stow it. Arkwin’s proven designs are capable of >250,000 cycles with the application of high external loads. Our thrust reverser system actuators operate at pressures up to 5,000 psig and feature multiple integrated control features for filtration, flow, and directional control. We offer multiple mounting options, linear position sensing transducers, 3”+ diameter bores, and 25”+ strokes. Arkwin advanced locking mechanisms can be constructed from using feature multiple pawl configurations depeding the application requirements. Locks can be integrated with visual and electrical lock indication or position sensing. Arkwin designs unlock with loads up to 20,000 pounds and hold over 33,000 pounds in operation.