Precise Craftsmanship. Exacting Quality.

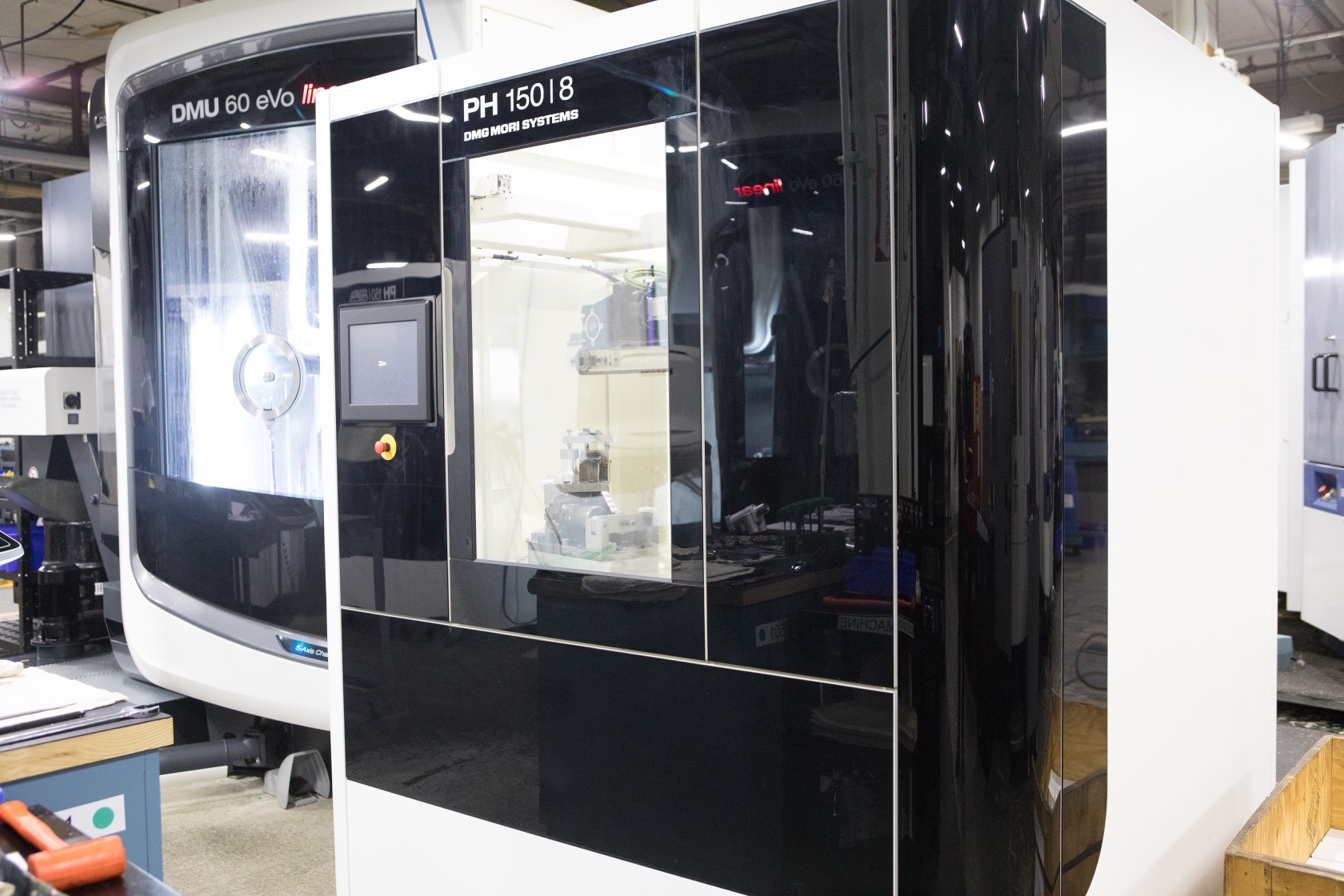

Our machinery includes some of the most advanced Computer Numerically Controlled (CNC) multiple-operation machine tools in the world. Our equipment is linked to our Computer Aided Manufacturing (CAM) network to permit exact integration and perfect quality between design and manufacturing. In fact, we can meet spool and sleeve tolerances as precise as 30 millionths of an inch.

All assembly is done by our highly skilled and experienced craftsmen. Because we house assembly and testing in the same building, we can complete projects in hours, not weeks.

We spray a variety of coatings, including mil-spec aviation standard coatings and flame-resistant coatings. As you would expect, we do 95% of it in-house.

We design and fabricate all our tooling in-house. Our expert staff of toolmakers gives us an advantage by allowing us to prioritize quick turn solutions as well as control timing, quality, and cost.

We have the ability to conduct in-house contamination sampling testing using many types of fluid, including the following:

• Petrol-based fluids

• Phosphate ester fluids

• Turbine Oil

• Calibration Fluid

• Jet Fuel

• Silicon fluid

• High-Temperature air

We conduct non-destructive testing using magnetic particle inspection and fluorescent penetrant inspection.